Medium temperature: ≤80 ℃

Operating mode: Manual

medium: Water

caliber: 2 "-12"

Pressure: 125-150LB

Body material: Ductile iron

Connection method: Flange

| ANSI soft stem gate valve Material of main parts | ||

| Part Name | material | |

| Body / bonnet | Ductile iron | |

| gate | Ductile iron + EPDM | |

| Valve stem | stainless steel | |

| Stem nut | Brass / Ductile Iron | |

| ANSI soft stem gate valve Performance Specification | |||||||

| model | Nominal pressure | Test pressure (mpa) | proper temperature | Applicable medium | |||

| Strength (water) | Sealed (water) | ||||||

| Z41X-125LB | 125LB | 1.50 | 1.10 | ≤80 ℃ | water | ||

| Z41X-150LB | 150LB | 2.40 | 1.76 | ≤80 ℃ | water | ||

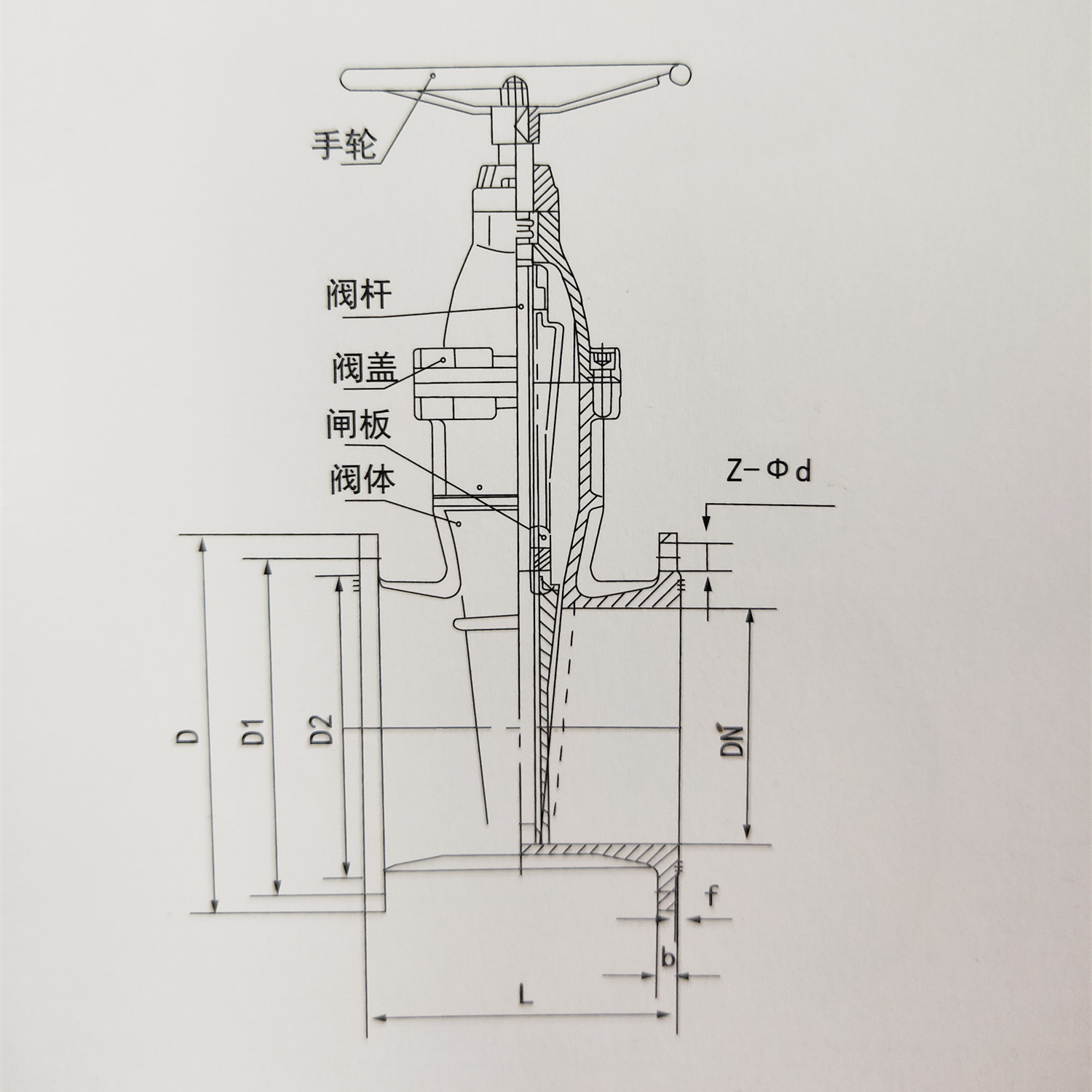

| ANSI soft stem gate valve Z41X external dimensions and connection dimensions | |||||||

| model | Nominal diameter (mm) | inch | Size (mm) | ||||

| L | D | Waterline table diameter | nd | ||||

| Z41X-125 / 150LB ANSI soft stem gate valve | 50 | 2" | 178 | 152 | 121 | 4-19 | |

| 65 | 1 1/2 " | 190 | 178 | 140 | 4-19 | ||

| 80 | 3 " | 203 | 191 | 152.4 | 4-19 | ||

| 100 | 4 " | 229 | 229 | 190.5 | 8-19 | ||

| 125 | 5 " | 254 | 254 | 216 | 8-22 | ||

| 150 | 6 " | 267 | 279 | 241.3 | 8-22 | ||

| 200 | 8" | 292 | 343 | 298.5 | 8-22 | ||

| 250 | 10 " | 330 | 406 | 362 | 12-25 | ||

| 300 | 12 " | 356 | 483 | 431.8 | 12-25 | ||

Features

-Visual operation: The valve stem rises and falls synchronously with the opening and closing of the valve, allowing for intuitive judgment of the valve switch status and facilitating operation and management (although the visible stem is not directly mentioned, the comparison of the "hidden stem" in the middle can infer the characteristics of the visible stem).

-International universality: manufactured according to American National Standards Institute (ANSI) standards, adapted to international project requirements, ensuring compatibility with pressure ratings, size specifications, and global pipeline systems.

-Elastic seal: The valve stem and sealing ring are made of soft materials (such as rubber or EPDM), combined with three "O" ring designs to reduce friction resistance, ensure stable sealing performance, and have a long service life

-Leak prevention guarantee: The soft sealing structure can compensate for slight deformation and avoid medium leakage, especially suitable for frequent opening and closing scenarios.

-Epoxy resin coating: The valve body cavity is coated with non-toxic epoxy resin to prevent corrosion, suitable for drinking water and sewage systems

-The bottom of the valve seat is designed to be flush with the pipeline, avoiding the accumulation of impurities and ensuring the cleanliness of the sealing surface and long-term sealing reliability

Copyright © Hebei Yaosheng IM & EX Trading Co.,Ltd. All Rights Reserved |Sitemap | Technical Support: